Forging processes have evolved over centuries, incorporating a variety of methods suited for different applications and materials. Offering superior strength and structural integrity compared to other metalworking techniques, forging plays a crucial role in industries such as aerospace, automotive, and heavy machinery.

Different forging processes offer unique benefits. Processes are chosen based on factors like material type, production volume, and desired mechanical properties. Explore each of these widely-used forging techniques:

- Open die drop hammer forging

- Closed die forging

- Press forging

- Rolled ring forging

- High energy rate forging (HERF)

- Plastic deformation

Whether you are an engineer, manufacturer, or industry professional, understanding the distinctions between these forging processes can help you make informed decisions for design and production needs.

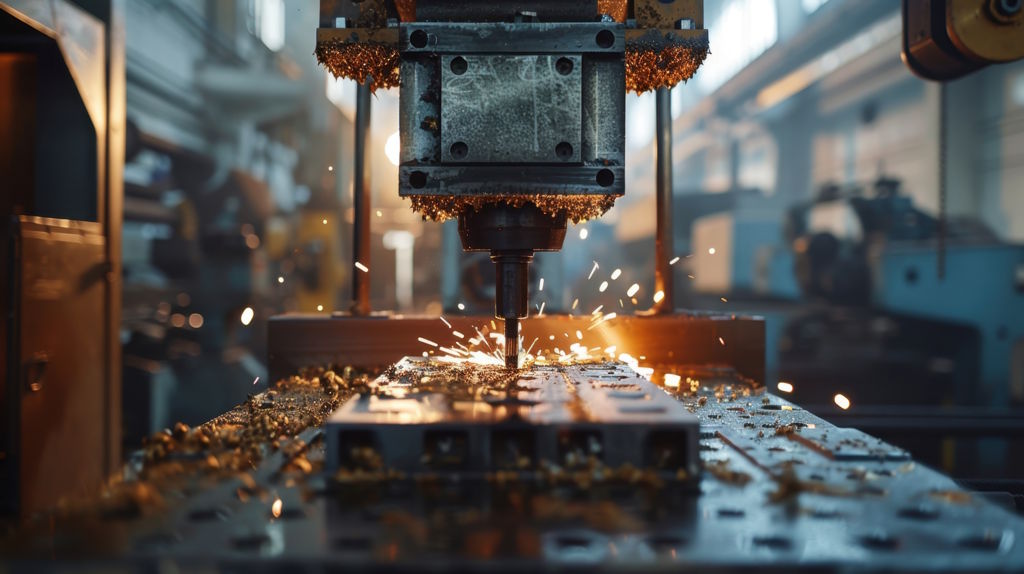

Open Die Drop Hammer Forging

With open die forging, a hot billet or ingot is placed under a hammer and formed into the desired shape. The smith move the material as it is shaped, lending this type of production to components that are custom made.

Closed Die Drop Forging

With closed die forging, the heated billet or ingot is hammered into a die that resembles a mold of the desired parts. As the materials are struck, the metal will be forced into the cavities of the die. This process creates a forged part that closely resembles the final desired shape.

Also known as impression die forging, closed die forging is well-suited for high-strength, high-performance components. It is widely used in automotive, aerospace, and industrial applications. Common parts produced through this method include connecting rods, crankshafts, gear blanks, and other components that demand durability and precision.

The closed die forging process offers several advantages, including:

- Excellent dimensional accuracy

- Improved surface finish

- Enhanced mechanical properties

Press Forging

Press forging presses the metal into a desired shape in a slower process compressing the metal inside the piece as well. Unlike drop forgings, which use multiple strikes to form the metal, press forgings use tremendous pressure. The ability to deliver consistent pressure over a controlled time period allows press forgings to create exact strain rates and closer tolerances.

This is also one of the more economic forging processes available. Entire components can be formed in one press, with fewer size limitations. Unlike drop hammer forging, which only deforms the exterior of the workpiece; press forging is able to deform both the exterior and total interior all at once.

Rolled Ring Forging

Ring rolling machines are a specialty forging machine for production of seamless rings, essential for items such as large ring gears and bearing races. A “donut” shape of metal, first formed on a forging press, is placed over a spindle, called a “mandrel”, of the rolling machine, spearing the hole of the “donut”. Rolling dies then press against the donut, squeezing the blank between those rollers and the mandrel while all the elements rotate to spin the blank and shape it into a ring of ever increasing diameter.

High Energy Rate Forging

HERF machines are not in widespread commercial production but serve a niche where forming material at an extremely high speed provides some essential advantage to the end product. These machines resemble a highly modified forging hammer and the item produced is typically formed in a single “shot”.

Plastic Deformation

Deformation of a metal in a “solid state” is, technically, the description of forging. Thus, the specialty operations classified as rolling, extrusion, spinning, cold heading – anything that uses force to strain, provide shearing forces that drive recrystallization of the microstructure and/or change the bulk shape of the material can be considered processes related to, and associated with, forging.

Which Forging Process is Right For Me?

Each of the forging processes discussed above has unique characteristics and advantages. Choosing the right technique depends on a variety of factors, from the materials you’re using to the applications of the finished part.

Queen City Forging can help you find the best option for your needs. Contact us to speak with a forging expert and get your questions answered.

Queen City Forging’s No. 8 Chambersburg Die Forger was purchased new and installed for drop hammer forging. This hammer, with computer controls to program blow pattern, timing and blow energy, is “state of the art” forging hammer technology. This equipment is a significant upgrade from the die forging capabilities of our board drop hammers, and allows us to efficiently produce a greater variety of drop forgings to closer tolerances.