At Queen City Forging, we know how important reliability and precision components are to the medical industry. Our forged components are designed to meet the serious demands of medical applications, ensuring durability and performance even under extraordinary levels of impact loading and fatigue stresses.

Quality Materials and Precision Engineering

Our medical components are manufactured using top-grade materials such as medical-grade steel, aluminum, and titanium. Each material is chosen for its unique properties, and optimized to match the requirements of medical devices and equipment. Our engineering team employs state-of-the-art forging technology and precision engineering to deliver components that exceed industry standards.

Custom Solutions for Medical Applications

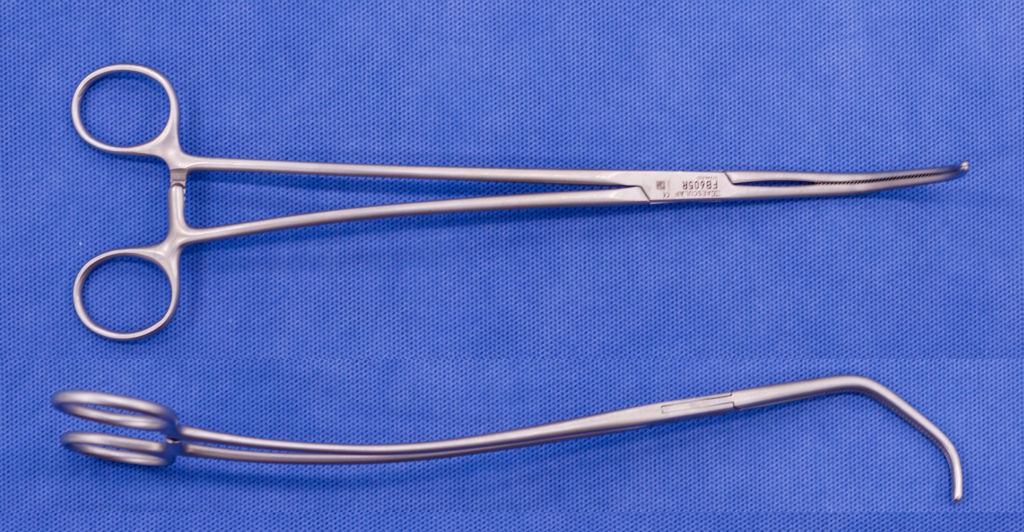

We specialize in providing custom solutions tailored to your specific needs. Whether you require components for surgical instruments, implants, or diagnostic equipment, our team will work closely with you to design and produce forged components that meet your exact specifications. We are committed to delivering solutions that enhance the safety and effectiveness of medical devices.

Benefits of Forgings in the Healthcare Field

The use of forged components in the medical field offers numerous advantages that are crucial for the safety and effectiveness of medical devices. Here are some of the key benefits:

- Enhanced Strength and Durability: Forged components are known for their superior strength and durability. This makes them ideal for medical applications where components must withstand high levels of stress and impact without failing.

- Improved Performance: The forging process aligns the grain structure of the metal, resulting in components with improved mechanical properties. This will make sure that the medical devices perform reliably and efficiently.

- Customizability: Forgings can be tailored to meet the precise specifications required for various medical applications. Whether it’s for surgical instruments, implants, or diagnostic equipment, forged components can be customized to achieve the desired shape, size, and properties required.

- Biocompatibility: Medical-grade materials such as steel, aluminum, and titanium used in forging are biocompatible, meaning they can be safely used in contact with body tissues and fluids. This is essential for implants and other internal medical devices.

- Cost-Effectiveness: While the initial cost of forging might be higher, the long-term benefits such as reduced failure rates and longer service life make it a cost-effective choice for medical device manufacturers.

- Precision and Accuracy: Advanced forging technologies and precision engineering produce components that meet the tolerances and specifications required in the healthcare industry. This precision is vital for the correct functioning of medical devices.

- Consistency: The forging process produces components with consistent quality and properties, which is critical for maintaining the reliability and performance of medical devices over time. Homogeneous metallurgy minimizes machining issues, reducing inspection and eliminating rejections due to voids, inclusions or other defects.

Request a Quote

Ready to learn more about how our forged medical components can benefit your projects? Contact us today to discuss your requirements and request a quote. Our team is here to provide the support you need to achieve your goals with confidence.

Experience the Queen City Forging difference and elevate the performance of your medical devices with our reliable, high-quality forged components. Let us help you deliver exceptional results.

Unwavering Commitment to Quality

- Quality is at the forefront of everything we do at Queen City Forging. Our rigorous quality control processes ensure that every component we produce meets the highest standards of precision and reliability. We understand the critical nature of medical applications, and our components are engineered to perform flawlessly even under the most demanding conditions.