Regardless of the material or end product, Queen City Forging produces unrivaled results. We have built an enduring reputation of delivering cost-competitive components that can survive the most demanding service applications.

Our specialty forgings maintain the exceptional properties of the wrought product, and can meet the needs of industries from aerospace to healthcare.

Specialty Forging Capabilities

Whether managing a complex supply chain or researching properties of new alloys, our unique capabilities allow us to:

- Match the right equipment and design processes to get the optimum manufacturing outcome

- Apply both internal and external design, combined with forging process research expertise

- Apply a full range of impression die forging equipment to optimize metallurgical benefits for small components manufacturing, including:

- Screw presses

- Mechanical presses

- Upset forging machines

- Hydraulic press

- Forging hammer

From railroad components to car engine parts, Queen City Forging has the expertise to deliver the specialty forge you need.

Solutions for a Range of Industries

Finished metal component parts made by Queen City Forging are used to meet the critical requirements of a range of industries, including:

- Aerospace

- Agriculture

- Automotive

- Construction

- Healthcare

- Railroads

- Transportation

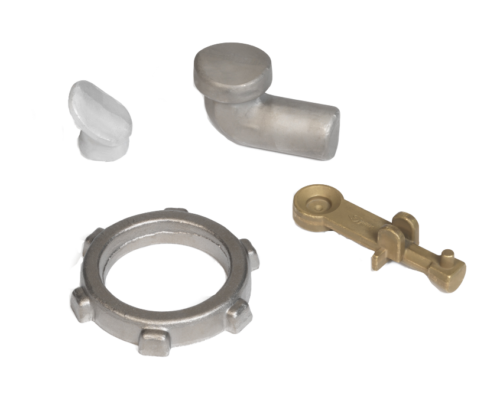

Examples of specialty forgings we can provide include:

- Small aircraft components

- Rail C&S

- Diesel engine parts

- Automotive power trains

- Agricultural equipment parts

- Heavy hinges

- Valve components

Are You Ready to Forge the Unforgeable?

If you have a metal component manufacturing project, please allow our team of forging specialists to explore solutions with you. You can start by telling us about your application or you can call us at 513-321-7200.

A History of Forging Success

We have had success working with high performance micro alloy, Ni strengthened, maraging, and stainless steels which are forged with special thermal handling operations to assure optimum metallurgical results.

We pride ourselves on our ability to successfully forge alloys designed for machinability that other shops turn away as unforgeable. Queen City Forging has developed special expertise in the utilization of its patented infrared aluminum heating process, improving the fatigue properties of aluminum alloys.

Masters of Forging Technology

Our success begins with our mastery of forging technology that is proven to:

- Match durability with cost-effective techniques

- Create a competitive advantage for our customers,

- Find solutions to the biggest design challenges faced by leading manufacturers