Aluminum Hot Forging Using Rapid Infrared Heating

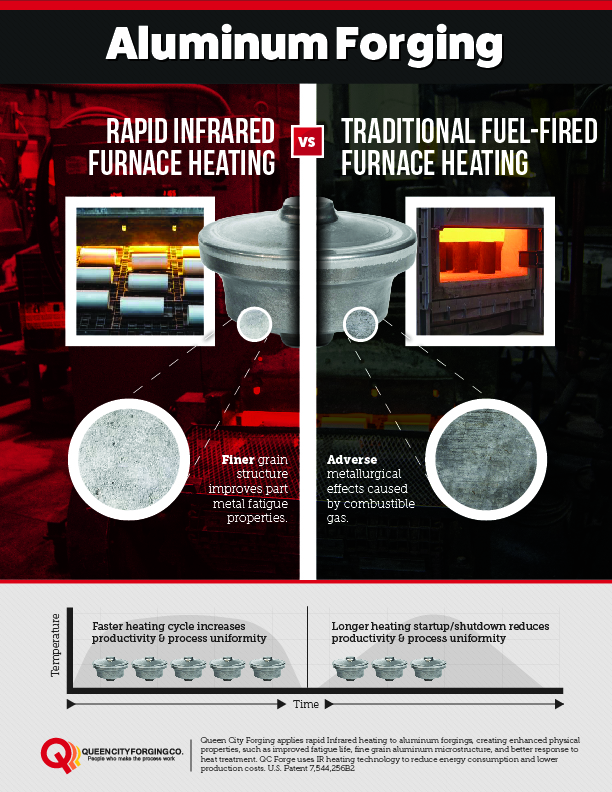

Queen City Forging applies rapid infrared heating to aluminum hot forgings, creating enhanced physical properties, such as improved fatigue life, fine grain aluminum microstructure, and better response to heat treatment. This infrared heating technology, which is exclusively available at Queen City Forging, reduces energy consumption and lowers production costs up to 50%.

Learn more about our patented rapid infrared heating technology, or request a quote for your aluminum hot forging project today.

Energy-Saving Hot Forging Process

Challenges facing U.S. forging companies include increasing demand for energy efficiency, cost reductions, and pressures of international competition. Volatile energy prices and the growing need for improved energy efficiency continue to force U.S. forging companies to adopt improved and cost-efficient techniques. When it comes to aluminum hot forging, Queen City Forging’s innovative approach to preheating the metal billets prior to hot forging offers significant energy savings.

Traditional Furnace Heating

In a conventional aluminum forging application, preheating of billets is typically achieved using convection gas-fired furnaces. However, low rates of heat transfer to the work piece, along with the need to heat both the furnace structure and the work piece, mean this method requires relatively long cycle times and is thermally inefficient.

Over the past few years, heating techniques have been developed using high-speed convection furnaces and induction furnaces producing higher heat transfer rates. Unfortunately, these provide only marginal improvements and present notable disadvantages. For example, induction furnaces can provide more efficient heating, but their use is limited by higher equipment costs and the geometry of the metal stock being heated. Induction furnaces often have problems coupling with aluminum alloys, and are unsuitable when reheating forgings requiring multiple aluminum forge cycles.

Rapid Infrared Heating

Addressing the inadequacies of the existing heating techniques, Oak Ridge National Laboratory, along with industrial and university partners, developed a hybrid infrared heating system that permits rapid and uniform heating of aluminum alloy billets prior to forging. The system can also be used for subsequent reheating of forgings requiring additional forging operations.

Benefits of Rapid Infrared Heating for Aluminum Hot Forging

Rapid Infrared (RI) heating has been proven to reduce the heating times by an order of magnitude, decrease energy consumption by factor of three, and produce forgings with enhanced metallurgical and mechanical properties.

Field testing of this hybrid infrared system in full-scale production setup demonstrated cost savings up to 40-50% through reduced energy consumption, increased throughput, and improved consistency in the process and quality of the product. This aluminum hot forging innovation is a proven process and a viable aluminum forging design consideration for today’s manufacturers.

This technology is exclusively available at Queen City Forging.

U.S. Patent 7,544,256B2

Looking for an Aluminum Hot Forging Company?

Take advantage of the cost savings and improved product quality offered by Queen City Forging’s rapid infrared heating technology for your aluminum hot forging project. Learn more about our aluminum forging capabilities or request a quote today.

Learn More About Rapid IR Aluminum Hot Forging

Aluminum Forging at Queen City Forging — article in the Business Courier

Download these PDF files:

- Application of Rapid Infrared Heating to Aluminum Forgings

- Rapid Preheating of Extruded Aluminum Billets for Energy Efficient Production of Forgings

- Supporting Industries Project Fact Sheet on Enhancement of Aluminum Alloy Forging

- Control of Grain Size and Age Hardening in AA2618 Forgings Processed by Rapid Infrared Radiant Heating

- Video Transcription for Aluminum Forging Innovation by Oak Ridge National Laboratory & Queen City Forging