At Queen City Forging, we’ve spent over a century improving impression die forging, enhancing craftsmanship with advancing technology. The goal is to deliver the highest performance from metal components to serve industries where failure isn’t an option. But what makes impression die forging—also known as closed-die forging—so advantageous?

Let’s explain the top benefits of this time-tested process and explore why it’s the go-to choice for demanding applications.

What is Impression Die Forging?

Before we get into the advantages, let’s quickly recap what impression die forging is. It’s a metalworking process where a heated metal bar or billet is shaped under high pressure between two dies. The dies contain a series of machined cavities that progressively form the desired part through a process of shaping blows forcing metal to conform to those die cavities.

The result is a near-net-shape component with improved metallurgical properties ready for use with additional work. At Queen City Forging, we use this method to craft everything from special alloy fluid impellers to farm equipment components. But, why choose this process over other metal forming options?

Top Advantages of Impression Die Forging

Impression die forging offers a unique combination of strength, precision, and efficiency, making it critical for industries that can afford nothing but the best. The top advantages of impression die forging include:

- Unmatched strength and durability

- Precision for complex shapes

- Material and cost efficiency

- Versatility across materials

- Enhanced production efficiency

- Improved safety and reliability

Unmatched Strength and Durability

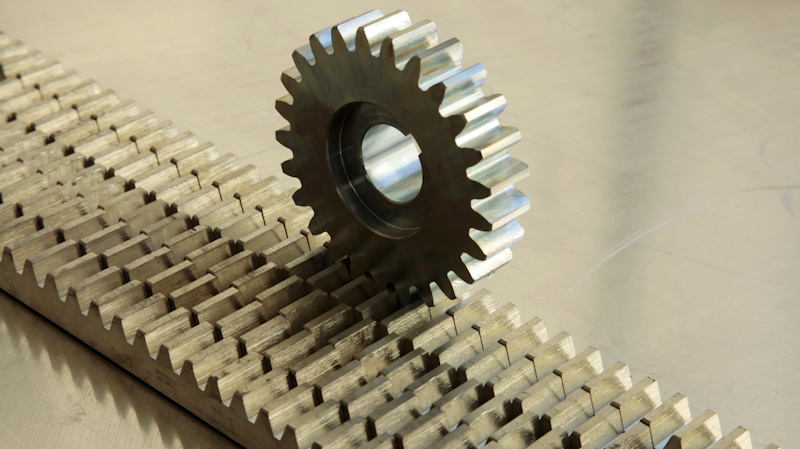

Impression die forging creates parts with exceptional strength by aligning the metal’s grain structure in with the shape of the component. This continuous grain flow enhances resistance to fatigue, impact, and wear—qualities that machined or cast parts can’t match. For example, a forged steel gear for a rail system can withstand years of heavy loads without cracking, while a cast gear might fail under the same stress.

At Queen City Forging, we’ve seen our agricultural clients benefit from forged components that endure extreme conditions, like heavy equipment parts that handle repeated high-impact uses. The properties forging creates are essential for safety critical parts or where failures in the field amount to delays, expense and potential warranty costs.

Precision for Complex Shapes

The dies in impression die forging are custom machined to exact specifications, allowing us to produce intricate shapes with tight tolerances. This precision is critical for industries like medical device manufacturing, where a component must have both dimensional precision and uniform predictable internal structure to assure component performance. Unlike casting, which can result in defects like porosity, forging ensures consistency across every part.

One of our rail clients needed electromechanical component parts with precise dimensions and consistent, uniform metallurgy for magnetic properties. Impression die forging delivered parts that met specs with zero defects, an absolute requirement for a safety critical item.

Material and Cost Efficiency

When impression die forging produces near-net-shape parts, it reduces the need for extensive machining. Opposed to machining from solid, which can waste material and machine time, forging to near or more nearly net is a benefit. For instance, machining a component from a solid block might waste 50% or more of the material, while forging can cut that waste to under 10%. Working with high-cost alloys or when materials are in short supply, starting with a forging that represents less raw material is a benefit. At Queen City Forging, we’re committed to sustainability, and this efficiency helps us minimize scrap while lowering costs for our customers.

Versatility Across Materials

Impression die forging works with a wide range of metals, from aluminum and steel to titanium and high-performance or copper-based alloys. Whether you need a lightweight aluminum bracket for aerospace or a corrosion-resistant bronze gear for salt water, impression die forging can handle it.

At Queen City Forging, we’ve forged components in over 50 different alloys and material grades, tailoring material choices to each client’s specific needs. This versatility makes the process ideal for diverse industries with unique requirements.

Enhanced Production Efficiency

Impression die forging is well-suited for both small and large production runs. Once the dies are made, with raw material on hand, we can produce parts quickly and consistently, making it a cost-effective choice when demand schedules change weekly.

For example, a turbocharger customer revised their schedule with a drop-in expedited order requiring alternate tooling and a change in raw material input size and cut length. With tools and raw material inventory on hand, we were producing the urgent requirement within three days. As a small business, our ability to shift production quickly to meet changing demands with no sacrifice to quality is a major benefit we offer customers.

Improved Safety and Reliability

Forged parts are free of internal defects like voids or inclusions, which are common in casting. This reliability is crucial for safety-critical applications. Imagine a forged valve in a high-pressure chemical process. Flawless forged structure ensures the best insurance against failure. We strive for failure rates that are not just one in a million, or one in ten million. Our goal is to produce forge components where abuse and misuse are shrugged off; where when all else fails, the essential forged component is still serviceable.

Why Choose Queen City Forging for Impression Die Forging?

At Queen City Forging, we don’t just offer impression die forging—we elevate it. Here’s what sets us apart:

- Experience You Can Trust: With over 100 years in the forging industry, we’ve mastered the nuances of impression die forging to deliver unmatched quality.

- Cutting-Edge Technology: Our advanced forging presses and simulation software ensure precision and efficiency in every project.

- Custom Solutions: From first article to full production, we work closely with you to meet your exact specifications.

- Certified Quality: We’re ISO 9001:2015 certified, so you can be assured our system works to meet all your requirements.

Is Impression Die Forging Right for Your Project?

If your industry demands components that are strong, precise, and reliable, impression die forging is likely the answer. It’s a process that delivers value through durability, efficiency, and versatility—qualities that translate to better performance and lower costs over the life of your product.

Ready to explore how impression die forging can benefit your next project? Whether you’re in aerospace, rail, medical, or automotive, Queen City Forging is here to help you forge the future.

Get Started with Queen City Forging

Impression die forging offers advantages that other metalworking methods simply can’t match. At Queen City Forging, we’re passionate about using this process to create components that power innovation and reliability across industries.

Contact us today to discuss your project needs. Call us at 513-321-7200 to get started. Let’s create components that can meet or exceed the toughest requirements.

Filed under: Forging Benefits, Types of Forging