When it comes to the world of metalworking, the hot forging process stands out as a cornerstone technique that shapes the very fabric of our modern industry. But what exactly is hot forging, and why is it so essential?

What is Hot Forging?

Hot forging is a metalworking process that involves shaping a piece of metal by heating it to a high temperature and then applying pressure. This technique enhances the metal’s ductility, making it easier to form into desired shapes without cracking. Typically, the metal is heated to a temperature that exceeds its recrystallization point, which for steel is above 1,000 degrees Celsius (1,832 degrees Fahrenheit). At these elevated temperatures, the metal becomes malleable and can be molded into complex shapes with precision.

The Steps of the Hot Forging Process

The hot forging process consists of several critical steps:

- Heating: The metal is heated in a furnace until it reaches the appropriate forging temperature. This step is crucial as it ensures the metal is malleable enough to be shaped without breaking. The temperature will vary depending on the material. It is also important to get the correct heat, not to overheat or underheat.

- Forming: Once heated to the exact temperature, the metal is swiftly transferred to a forging press or hammer, where it is shaped under immense pressure. Dies (custom molds) are used to achieve the desired form.

- Cooling: After forming, the metal is gradually cooled. This controlled cooling process, known as quenching, helps to set the new shape and improve the metal’s properties. If not cooled properly the properties could be diminished.

- Finishing: Finally, the forged piece may undergo additional finishing processes, such as trimming, machining, or heat treatment, to enhance or perfect the final characteristics.

When is Hot Forging Used?

Hot forging is employed in a variety of applications due to its ability to produce strong, durable components with superior mechanical properties. Here are some common scenarios where hot forging is the method of choice:

Automotive Industry

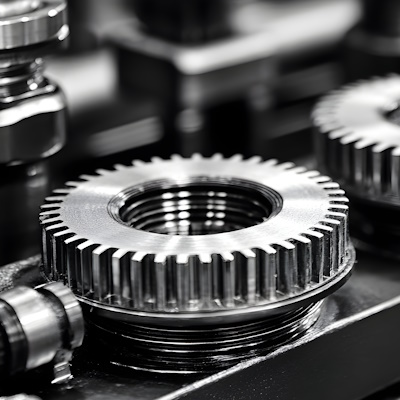

In the automotive sector, hot forging is used to manufacture critical components such as crankshafts, connecting rods, and gears. The strength and durability created by hot forging are crucial for the automobile industry, as these components must endure significant stress and wear.

Aerospace Industry

The aerospace industry relies on hot forging to produce high-performance parts that can endure extreme conditions. Turbine blades, structural components, and landing gear are often hot-forged to ensure they meet stringent safety and performance standards.

Construction and Heavy Machinery

Hot forging is also prevalent in the construction and heavy machinery industries. Components like bolts, nuts, and various structural elements are hot-forged to provide the necessary strength and resilience required in these demanding environments.

Medical Devices

Even in the medical field, hot forging plays a role. Surgical instruments and implants are hot-forged to achieve the precise shapes and mechanical properties needed for medical applications.

Why Choose Hot Forging?

Hot forging offers several advantages over other metalworking techniques:

- Enhanced Strength: The process refines the grain structure of the metal, resulting in improved mechanical properties and increased strength.

- Versatility: Hot forging can be used to create a wide range of shapes and sizes, from small precision parts, that Queen City Forging specializes in to large structural components.

- Cost-Efficiency: While the initial setup may be costly, hot forging is highly efficient for large-scale production, reducing overall costs.

At Queen City Forging, we take pride in our expertise in hot forging. Our commitment to quality and precision ensures that every forged component meets the highest standards. Whether you need parts for automotive, aerospace, construction, or medical applications, our hot forging process delivers exceptional results.

Understanding the hot forging process and its applications not only showcases the importance of this technique but also highlights the innovation and craftsmanship behind every forged piece. At Queen City Forging, we continue to push the boundaries of what is possible, forging a path to a stronger, more resilient future.

Filed under: Forging Process, Forging Benefits, Forging Innovation, Forging Parts