At Queen City Forging, we’ve been mastering the art and science of forging for over 100 years. We deliver high-quality, durable metal components to industries like automotive, rail, and medical. One of our core techniques is impression die forging—a process that combines precision, strength, and efficiency to create parts that stand the test of time.

What exactly is impression die forging, and why does it matter? Let’s break it down in a way that’s easy to understand, whether you’re a manufacturer, engineer, or just curious about metalworking.

Impression Die Forging

Impression die forging—also called closed-die forging—involves heating up a piece of metal, putting it in a specialized tool called a die, and applying pressure. Here’s how it works:

- Heat the Metal: A metal billet (a solid piece of material like steel, aluminum, or titanium) is heated to a high temperature, making it malleable but not molten.

- Place in the Die: The heated billet is placed into the lower half of a two-part die. A die is a tool that has a custom-shaped cavity designed for the specific part being forged. The shape of the die is what determines the shape of the part.

- Apply Pressure: A powerful press or hammer forces the upper die down, squeezing the metal into the shape of the die’s impression.

- Trim and Finish: Excess metal (called flash) is trimmed away. The part may undergo additional finishing processes like heat treatment or machining.

The result? A near-net-shape part that’s incredibly strong, precise, and ready for demanding applications.

Why Choose Impression Die Forging?

At Queen City Forging, we specialize in impression die forging because it offers unique advantages that make it ideal for industries where performance and reliability are non-negotiable. Here are the top benefits:

Superior Strength and Durability

Impression die forging aligns the metal’s grain structure with the shape of the part, creating a continuous grain flow that enhances strength. This makes forged parts far more resistant to fatigue and impact compared to cast or machined components. For example, a forged aerospace landing gear component will withstand extreme stresses that a cast part could not be expected to survive.

Precision and Consistency

The dies used in this process are custom-machined to exact specifications, ensuring each part is consistent in shape and size. Shaping during the forging process reduces the need for extensive machining, saving time and money while maintaining tight tolerances—critical for industries like medical device manufacturing.

Material Efficiency

Impression die forging produces near-net-shape parts. This means less material is wasted compared to processes like machining, where you start with a much larger block of material and cut away until you get the shape you desire. At Queen City Forging, we’re committed to sustainability, and this efficiency helps reduce scrap and lower costs for our clients.

Versatility in Materials and Shapes

From aluminum to titanium to high-performance alloys, impression die forging works with a wide variety of metals. It can also create complex shapes—like gears, flanges, or brackets—that would be difficult, inefficient, and costly to achieve with other methods.

Real-World Applications of Impression Die Forging

Impression die forging isn’t just a theoretical process—it’s the backbone of many industries that rely on Queen City Forging for their components. Here are a few examples:

- Agricultural: Heavy duty machinery that must withstand extreme environmental conditions, performance pressures, and still perform day after day.

- Automotive: Critical parts like gears and turbo chargers that must endure extreme temperatures and stresses to assure acceptable service life.

- Rail: Forged components, used in signaling system relays and switches, provide the durability and reliability needed for heavy-duty transportation that assures safe operations.

- Medical: Precision-forged components for CT scanners and other diagnostic equipment assure optimum care for critically ill patients.

The Queen City Forging Difference

At Queen City Forging, the goal is to produce forgings that optimize the manufacturing process. With over a century of experience, we’ve honed our craft to deliver unmatched quality and innovation. Here’s what sets us apart:

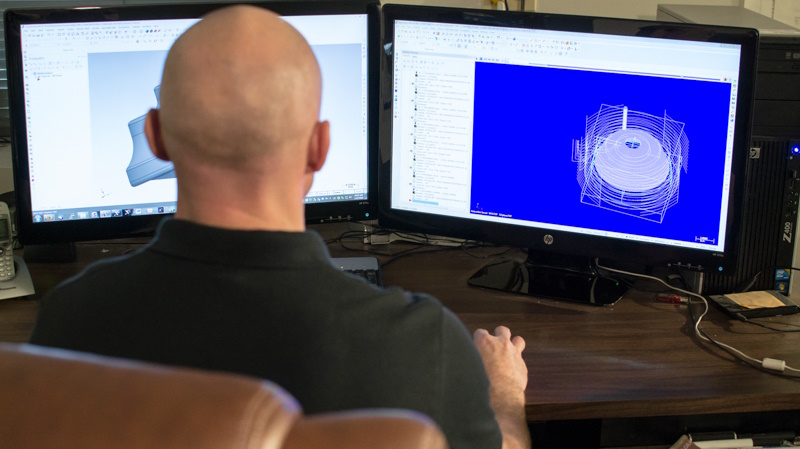

- Advanced Technology: We have continually upgraded controls and monitoring systems on our forging equipment and utilize simulation software to optimize die design.

- Expert Team: Our engineers and metallurgists bring decades of expertise to every project, from PPAP lot to production.

- Custom Solutions: Our goal is to provide forged raw material input to your process that optimizes material performance and manufacturability.

- Commitment to Quality: We’re ISO 9001:2015 certified, ensuring every part meets the highest standards.

Impression Die Forging vs. Other Methods

To give you a clearer picture, let’s compare impression die forging to other common metalworking methods:

Method: Impression Die Forging

Pros: High strength, precision, material efficiency.

Cons: Higher initial die cost, less suited for very small runs.

Method: Open-Die Forging

Pros: Flexible for large, simple shapes.

Cons: Less precise, more finishing required.

Method: Casting

Pros: Good for complex shapes, lower cost.

Cons: Weaker grain structure, potential for defects.

Method: Machining

Pros: High precision, no dies needed.

Cons: Material waste, weaker grain structure.

Impression die forging strikes a balance between strength, precision, and efficiency, making it the go-to choice for high-performance applications.

Why It Matters to You

If you’re in an industry that demands reliable, high-quality metal components, understanding impression die forging can help you make informed decisions about your supply chain. Choosing forged parts means choosing durability, precision, and long-term value—qualities that Queen City Forging has delivered since 1881.

Ready to see how impression die forging can benefit your next project? Whether you’re designing a new aerospace component or need a reliable partner for rail manufacturing, we’re here to help.

Let’s Forge the Future Together

Impression die forging is more than a process, it’s a solution for industries that can’t afford to compromise on quality. At Queen City Forging, we’re passionate about turning raw metal into components that power innovation and reliability across the globe.

Contact us today to learn how we can bring your ideas to life with impression die forging.

Filed under: Forging Process, Forging Benefits, Forged vs Cast, Types of Forging