Forging components from alloys, rather than from pure metals, offers several significant advantages that make alloys the preferred choice for many demanding applications. Here’s why making forgings out of alloys is beneficial:

- Enhanced mechanical properties

- Improved corrosion resistance

- Tailored properties for specific applications

- Better performance in high-temperature applications

- Cost efficiency

- Reduced weight with high strength

- Increased fatigue resistance

- Enhanced magnetic properties

Learn more about each of these benefits below.

Enhanced Mechanical Properties

- Strength and Hardness: Alloys often exhibit greater strength and hardness compared to pure metals. This is due to the combination of different elements that create a stronger, more durable material. For example, steel (an alloy of iron and carbon) is much stronger than pure iron.

- Toughness: Alloys can be engineered to be tougher, meaning they can absorb more energy before fracturing. This makes them ideal for components that must withstand high impact or stress.

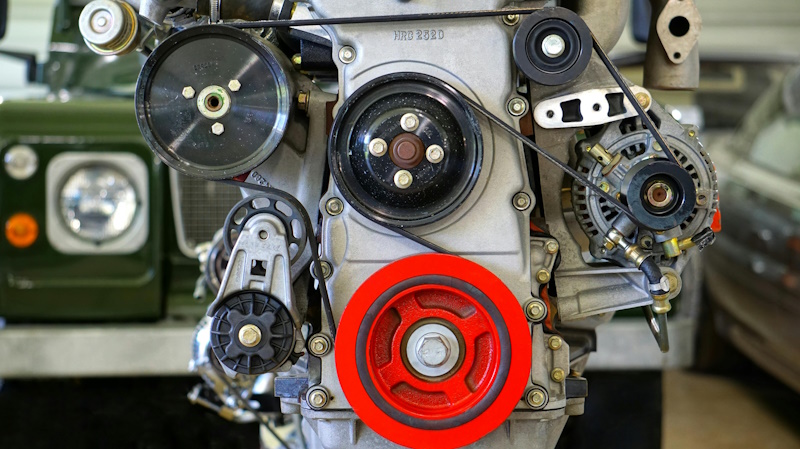

- Wear Resistance: Many alloys are designed to resist wear and tear better than pure metals. This is critical for parts that are subject to friction, such as gears or bearings.

Improved Corrosion Resistance

- Environmental Durability: Certain elements in alloys enhance the material’s resistance to corrosion. Examples include chromium in stainless steel or aluminum in various alloys. This makes alloy forgings ideal for use in harsh environments where pure metals might corrode quickly.

- Longevity: Forgings made from corrosion-resistant alloys last longer. This reduces maintenance costs and the need for frequent replacements in applications exposed to moisture, chemicals, or extreme weather.

Tailored Properties for Specific Applications

- Customization: Alloys can be designed with custom specific properties to suit particular applications. For instance, nickel-based alloy forgings are used in high-temperature environments because they maintain their strength and resist oxidation at elevated temperatures.

- Versatility: By adjusting the composition of the alloy, manufacturers can create materials with the exact balance of properties needed. This can include increased electrical conductivity, thermal resistance, or magnetic properties.

Better Performance in High-Temperature Applications

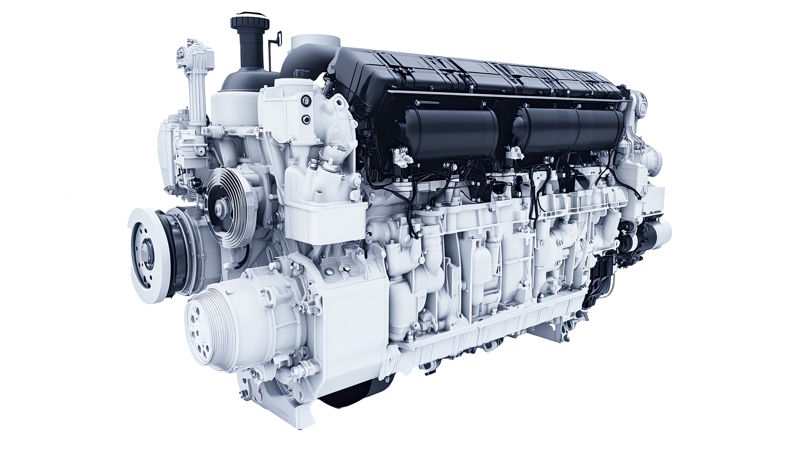

- Heat Resistance: Many alloys, such as those containing nickel, cobalt, or titanium, can withstand high temperatures without losing their mechanical properties. This makes them ideal for use in engines, turbines, and other high-heat environments.

- Stability: At high temperatures, pure metals can soften or deform. Alloys retain their shape and strength better, ensuring consistent performance under extreme conditions.

Cost Efficiency

- Material Efficiency: While some pure metals are too soft or too reactive for certain applications, alloying them can improve their performance and reduce the need for expensive or rare materials. This allows manufacturers to use less costly base metals while still achieving high-performance characteristics.

- Process Efficiency: Forging alloys can also reduce machining and processing time because they can be tailored to have better formability and machinability.

Reduced Weight with High Strength

- Lightweight Alloys: Aluminum and titanium alloys offer a high strength-to-weight ratio. This is particularly beneficial in industries like aerospace and automotive, where reducing weight while maintaining strength is critical.

- Fuel Efficiency: Lighter materials help in reducing fuel consumption in vehicles and aircraft. This contributes to overall cost savings and environmental benefits.

Increased Fatigue Resistance

- Durability: Alloy forgings can be designed to resist fatigue, which is the weakening of material caused by repeatedly applied loads. This is crucial for components that undergo cyclical stresses, such as connecting rods in engines or landing gears in aircraft.

- Safety: The improved fatigue resistance of alloy forgings helps prevent catastrophic failures in critical applications, enhancing overall safety.

Enhanced Magnetic Properties

- Magnetic Alloys: Certain alloys are specifically engineered for their magnetic properties, which are essential in electrical applications like transformers, motors, and generators. For example, silicon steel is an alloy used in electrical steel forgings for its superior magnetic characteristics.

Forging Alloys

Forging components from alloys offers numerous benefits, including enhanced mechanical properties, improved corrosion and wear resistance, better performance in high-temperature applications, and tailored material characteristics for specific needs. Alloys provide the versatility and durability required in critical industries like aerospace, automotive, energy, and electronics, making them the preferred choice for forging high-performance parts.

Filed under: Forging Materials, Forging Benefits, Forging Parts, Extend Life of Parts